Vibratory Motors Manufacturer

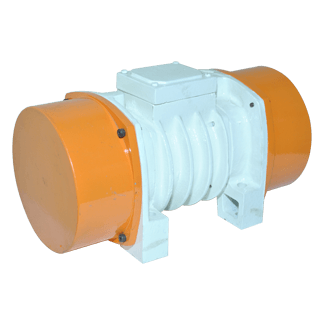

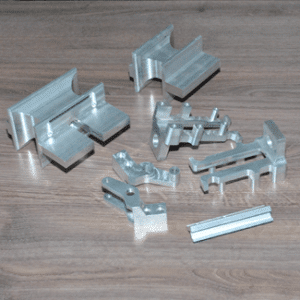

The vibratory motors we produce have a robust design, are stable under load, and vibration resistant, and have well-resin-impregnated windings & durable cylindrical roller bearings. N. Das Industries is a renowned manufacturer and supplier of high-quality vibratory motors, including electromagnetic vibrating motors and unbalanced vibrator motors, in India. From Gujarat (India), we are a noteworthy vibratory motors manufacturer. Precision-engineered design as per the industry-stated norms & standard qualification. N. Das Industries is a well recognized firm manufacturing best quality machine parts including vibratory motors. Having expertise of fabrication of entire inventory of parts of seed processing machines, we have designed an extensive range of CNC turned parts and unbalanced vibratory motors considering different kinds of seed processing levels.

We offer our variety of motors for vibrating feeders, vibrating screens and vibratory tables. Our chain of vibratory motors offers 750, 1000 and 3000 vibrations per minute. It is planned for directional vibrations and circular vibrations. Vibratory Motors are the core practical part of all kinds of seed processing machines. Every level of seed processing needs vibrator to make even, effective and uniform procedure.

We have encompass whole functioning of vibratory motors in different industrial operations like conveying, feeding, cleaning, screening, emptying and testing of seeds and beans and other products and materials. Due to its precise functioning and better durability, it is first choice of manufacturers of units of food processing and pharmaceuticals. It is also used for chemical and fertilizer industry.

Our inventory comprises foot mounted vibratory motor, electric vibratory motor, single phase vibratory motor and unbalanced vibrator motors. We also offer an exclusive series of VMC machined parts, precision CNC components, precision machined components and seed processing machine parts.

Products Range

What is Vibratory Motors ?

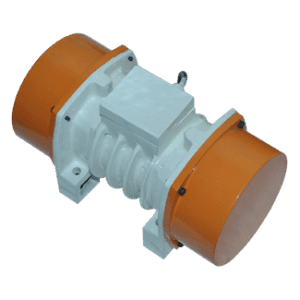

Vibratory motor is a compact size coreless DC motor used to informs the users of receiving the signal by vibrating, without sound. Vibratory motors are broadly used in a variety of applications including mobile phones, handsets, pagers, etc.

The principle components of vibratory motor is the magnet coreless DC motor are permanent, which means it will always have its magnetic properties (not at all like an electromagnet, which just acts like a magnet when an electric current goes through it); another fundamental element is the extent of the motor itself is small, and thus lightweight.

Moreover, the noise and the power consumption that the motor produce while using are low. Based on those features, the performance of the motor is highly reliable.

Why Us ?

Motor Solution: When you need any special motor requirement for new Application, motor service and repair and Parts trust Reliable Electric Motor Solutions. We absolutely cover it all, from all our Products, and will get the job done conveniently located in Ahmedabad, Gujarat, India.

High Performance: For over many years, Our Company has focused on keeping our motor running at optimum performs.

Configurable: As per costumer configuration, development is possible which depend on use, performance, life and reliable cost discussion.