India's Premier Vibratory Motors Manufacturers, Suppliers

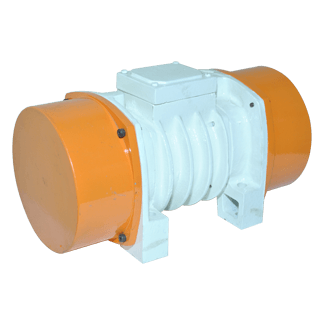

Our sophisticated vibratory motors are designed to drive feeders, vibratory screens, conveyors, silos, and other industrial machinery with unprecedented efficiency and reliability. N. Das Industries is a prominent vibratory motor manufacturer, Supplier, and exporter in India, providing quality-select solutions for various material handling requirements.

Fitted with entirely enclosed 3-phase squirrel cage induction motors, our design incorporates changeable eccentric weights on the ends of the shafts to provide precise vibrations for conveying, compacting, dosing, cleaning, testing, and feeding processes. Plastics, petrochemicals, cement, mining, food processing, pharmaceuticals, chemicals, power plants, and packaging industries benefit from our motors, which provide consistent and dependable performance under heavy loads.

With strong infrastructure and a focus on innovation, we supply products of international quality standards along with immediate after-sales service. With strong business ethics and a customer-oriented focus, N. Das Industries remains the favored choice for industries in India as well as abroad.

Products Range

Most Reliable Vibratory Motors Exporters Worldwide | Vibrating Feeder Motor Manufacturers in India

What is Vibratory Motors ?

A top-tier manufacturer of Vibratory Motors delivering advanced vibration solutions for industrial machinery across worldwide markets.

Vibrator motors are designed as electric motors used to create vibration to suit many industrial and business purposes. They are used as drive components in vibratory machinery like feeders, screens, conveyors, and silos to facilitate effective material handling without the necessity for elaborate mechanical systems.

From mining, cement, petrochemicals, food processing, pharmaceuticals, power plants, and packaging industries, vibratory motors are depended upon for conveying, compacting, dosing, cleaning, testing, and feeding applications with unparalleled reliability.

Why Us ?

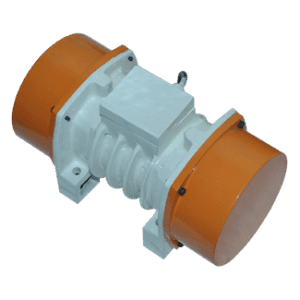

Motor Solution: We provide high precision, custom-engineered solutions including vibratory motors used in new applications, replacements, or repairs from here in Ahmedabad, Gujarat, India.

High Performance: Our vibratory motors are designed for high performance and long life so that you can be assured of temporary uninterrupted service, even when under full load.

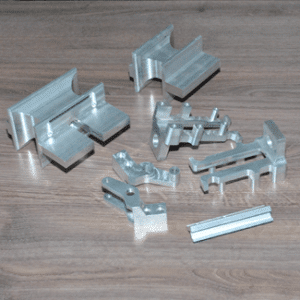

Configurable: We can create custom designed based on customer information, which guarantee maximum operational life, efficiency, and cost.

Vibratory Motor RPM Range Chart and Application

The vibratory motor RPM range is a very important element in the vibration frequency, material flow efficiency, and the overall performance of the equipment. Vibratory motors used in industry normally run at a speed of 750 RPM to 3000 RPM, and various RPM ranges are applicable in particular applications. Low RPM motors produce high-amplitude vibrations in heavy materials, whereas high RPM motors produce as rapid and low-amplitude vibrations, which are beneficial in screening and separation. The right choice of the RPM range will guarantee an effective working process, decreased equipment wear, and increased life cycle in the spheres of material handling, mining, building, and processing.

| RPM Range | Pole configuration | Vibration Features | Uses |

| 750-1000 RPM | 8 Pole | Pole Low frequency, high amplitude | Compaction machines, heavy-duty material handling, bin activators |

| 1200-1500 RPM | 6 Pole | balanced force | Vibratory feeders, hoppers, conveyors. |

| 1800 RPM | 4 – 6 Pole | Controlled vibration Output | Packaging lines, Process equipment |

| 2800-3000 RPM | 2-4 pole | High frequency & low amplitude | Vibratory screens, sieves, grading and separation systems |